Brand:BENTLY NEVADA

Model: 60M100

Status: New/Used

The Bently Nevada 60M100-00 Condition Monitoring System is a high-performance industrial grade platform designed for continuous real-time monitoring of rotating machinery and critical factory assets. This platform is developed specifically for industries such as oil and gas, power generation, petrochemicals, and heavy manufacturing. The 60M100-00 integrates advanced sensing, data acquisition, and diagnostic functions into a compact and robust system. Its modular architecture supports scalable monitoring - from a few key points to a network covering the entire factory - while transmitting precise vibration, temperature, and process data to predictive maintenance software.

BENTLY NEVADA 60M100

BENTLY NEVADA 60M100 Condition Monitoring System

The 60M100 Condition Monitoring System continuously monitors wind turbine machine trains using sophisticated signal processing algorithms and machine operating states.The 60M100 Monitoring System, as a part of condition-based maintenance, detects defects months in advance of a potential failure.

The 60M100 Monitor can be used in several configurations:

• As an independent, standalone condition monitoringsystem.

• A networked, distributed collection of inter-operatingsystems.

• As an integrated part of a machine OEM's control andinstrumentation package.

The 60M100 monitor includes features and advantages not provided in other systems. The monitor systems have all functionality required for condition monitoring of wind turbine machine trains including signal conditioning, alarming,configuration, speed inputs, and control system communication.

The system components include: 60M100 Monitor, Adapt.wind software, Transducers and cables.

Sophisticated signal processing algorithms extract dozens of measurements and health indices from each accelerometer point and can be custom tuned to specific bearing and gear box characteristics.

60M100 Overview

The 60M100 System is designed to monitor essential characteristics and components of a wind turbine, including:

• Tower sway• Main bearing

• Main rotor

• Gear boxeso

▫ All internal bearingso

▫ All bear mesheso

▫ Debris monitoring

•Generator bearings

•Generator grounding

If you need assistance configuring your monitoring solution, contact your local Bently Nevada sales professional or Bently Nevada support (bntechsupport.com).

Digital Communications

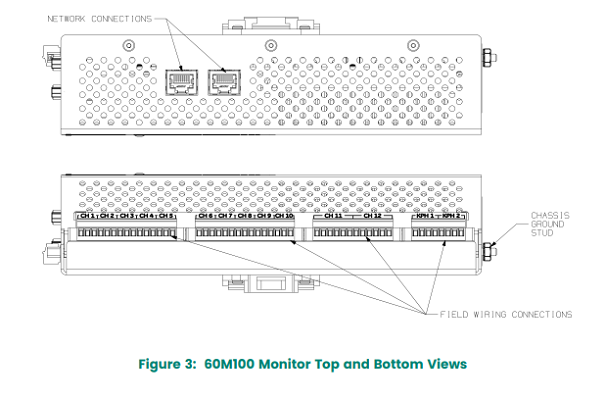

The 60M100 System includes digital communication capabilities for connection to ADAPT software using proprietary protocols via Ethernet connections. The 60M100 system transmits data via Ethernet TCP/IP. You can monitor values and status

your process and control and other automation systems.

provides extensive communication capabilities of all monitored values and statuses for integration with process control and other automation systems using Ethernet TCP/IP communications capabilities. It permits Ethernet communications with other 60M100 systems and System_Software. Supported protocols include:

Modbus/TCP

Industry standard Modbus protocol over TCP.The 60M100 supports both server and client mode.

System Features

The 60M100 monitors 150 static variables producing high resolution waveform data and trendllines.

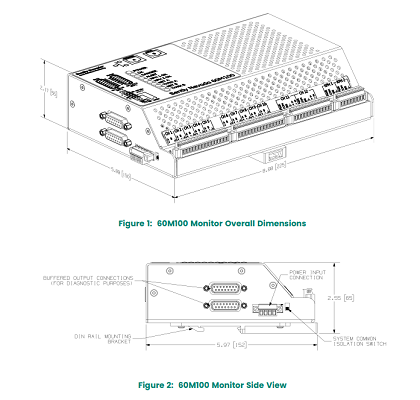

Capable of taking input from different sensor types, the 60M100 System can support up to 12 dynamic channel inputs, two Keyphasor signals, and digital communications. Channel 1 through channel 10 interface with 2-wire ICP type accelerometers. Channels 11 and 12 can be configured to interface with either 2-wire ICP type transducers or 3-wire proximity probes.Each dynamic channel can be independently configured with flexible signal processing options. The Keyphasor channels interface to either 3-wire proximity probes or other speed sensors which are powered externally.

The module provides enhanced capability for monitoring rolling element bearing machinery and gearing through its 24 bit Analog/Digital conversion and 40 kHz bandwidth design.

The 60M100 System is not a substitute for hard wired safety systems, nor does it replace the standard systems for the acquisition of operational data of the wind turbine.

Many products have not been launched yet. If you need more products, please contact us

Purchase consultation hotline: 18120742318

BENTLY NEVADA 60M100状态监测系统

60M100状态监测系统使用复杂的信号处理算法和机器运行状态连续监测风力涡轮机机组。作为基于状态的维护的一部分,60M100监控系统可以在潜在故障发生前几个月检测到缺陷。

根据风电场的规模,早期检测可以减少停机和生产损失,每年为您节省数十万至数百万美元的收入损失。借助60M100提供的先进知识,您可以提前安排维护停机和起重机操作,从而降低维护成本。

60M100监视器可用于多种配置:

•作为一个独立的状态监测系统。

•互操作系统的网络化、分布式集合。

•作为机器OEM控制和仪表包的组成部分。

60M100显示器具有其他系统所没有的功能和优点。监测系统具有风力涡轮机机组状态监测所需的所有功能,包括信号调节、报警、配置、速度输入和控制系统通信。

系统组件包括:60M100监视器、Adapt.wind软件、传感器和电缆。

复杂的信号处理算法从每个加速度计点提取数十个测量值和健康指数,并可以根据特定的轴承和齿轮箱特性进行定制调整。

60M100概述

60M100状态监测系统专为风力发电机组的连续永久监测而设计。它旨在监控需要极高可靠性和可用性的设备。

60M100系统旨在监测风力涡轮机的基本特性和部件,包括:

•塔架摇摆

•主轴承

•主旋翼

•齿轮箱o

▫ 所有内部轴承

▫ 所有熊mesho

▫ 碎片监测

•发电机轴承

•发电机接地

如果您需要配置监控解决方案的帮助,请联系您当地的Bently Nevada销售专业人员或Bently Nevadas支持人员(bntechsupport.com)。

数字通信

60M100系统包括数字通信功能,可通过以太网连接使用专有协议连接到ADAPT软件。60M100系统通过以太网TCP/IP传输数据。您可以监视值和状态

您的过程和控制以及其他自动化系统。

提供所有监测值和状态的广泛通信功能,以便使用以太网TCP/IP通信功能与过程控制和其他自动化系统集成。它允许与其他60M100系统和System_Software进行以太网通信。支持的协议包括:

Modbus/TCP

基于TCP的工业标准Modbus协议。60M100支持服务器和客户端模式。

系统功能

60M100监测150个静态变量,产生高分辨率波形数据和趋势线。

60M100是一个功能强大、用途广泛的状态监测系统,在一个紧凑、坚固的单元中提供基本的监测功能和先进的信号处理和规则。该模块调节输入信号以进行各种测量,并将调节后的信号与用户可编程的警报进行比较。

60M100系统能够从不同类型的传感器获取输入,最多可支持12个动态通道输入、两个键相器信号和数字通信。通道1至通道10与2线ICP型加速计接口。通道11和12可以配置为与2线ICP型传感器或3线接近探头连接。每个动态通道都可以独立配置灵活的信号处理选项。键相器通道与3线接近探头或其他外部供电的速度传感器连接。

该模块通过其24位模拟/数字转换和40 kHz带宽设计,为监测滚动轴承机械和齿轮传动提供了增强的能力。

60M100系统不能替代硬连线安全系统,也不能替代风力涡轮机运行数据采集的标准系统。

购买咨询热线:18120742318

QQ:3699232536