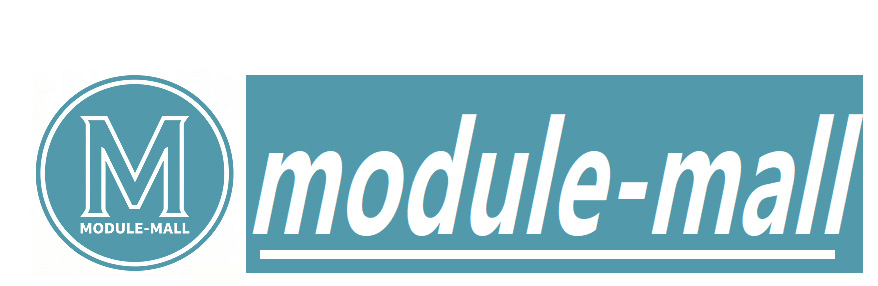

Brand:BENTLY NEVADA

Model: 3500-23E

Status: New/Used

The Bently Nevada 3500/23E Transient Data Interface Module is a data acquisition device designed specifically for industrial control systems. It can monitor and record the transient data of key mechanical components in real time, and is widely used in industries such as power, petroleum, and chemical, helping engineers discover and solve potential faults in a timely manner. Working voltage: 24V DC Signal type: Analog signal Sampling rate: 1000 times per second Interface type: RJ45 Protection level: IP65 Working temperature range: -20 ° C to+70 ° C Storage temperature range: -40 ° C to+85 ° C

BENTLY NEVADA 3500-23E

It is a data acquisition device designed specifically for industrial control systems. It can monitor and record the transient data of key mechanical components in real time, and is widely used in industries such as power, petroleum, and chemical, helping engineers discover and solve potential faults in a timely manner. Working voltage: 24V DC Signal type: Analog signal Sampling rate: 1000 times per second Interface type: RJ45 Protection level: IP65 Working temperature range: -20 ° C to+70 ° C Storage temperature range: -40 ° C to+85 ° C.

Bently Nevada 3500/23E is part of an online monitoring and protection system produced by Bently Nevada Corporation. The following is a detailed introduction to the system

Basic knowledge: Master certain basic knowledge, including the basic structure of CNC machine tools, the basic principles of NC machining, mechanical processing technology, and necessary CAD foundation.

Basic processes and key technologies: comprehensively understand and master the basic processes and key technologies of NC programming.

Software skills: Proficient in using a CAD/CAM software.

Practical experience: Rich practical processing experience. Sometimes, it is also necessary to master knowledge and experience in related disciplines such as molds.

Program quality: The quality of the NC program written.

Work efficiency: The work efficiency of NC programming.

Reliability and standardization level: The reliability and standardization level of NC programming (including standardization level of process planning, data file management, storage, and handover, etc.).

Work style: To maintain a rigorous and meticulous work style, each parameter setting should be repeatedly confirmed, and necessary checks and verifications should be carried out after the tool path calculation is completed.

Standardization and patterning of operations: NC programming operations should be standardized and patterned. According to the specific conditions of the enterprise, the technical specifications for NC programming are formulated, and the common parts (such as processing technology, cutting tools, etc.) in each operation link are patterned and standardized, which can effectively improve work efficiency and reliability.

Trial cutting inspection: Important processing procedures should undergo trial cutting inspection.

The above are the main functions and technical parameters of Bently Nevada 3500/23E.

Many products have not been launched yet. If you need more products, please contact us

Purchase consultation hotline: 18120742318

Email: [email protected]

以上就是Bently Nevada 3500/23E的主要功能和技术参数。

购买咨询热线:18120742318

QQ:3699232536